Unique color management tools and expertise for packaging & labels

Unique color management tools and expertise for packaging & labels

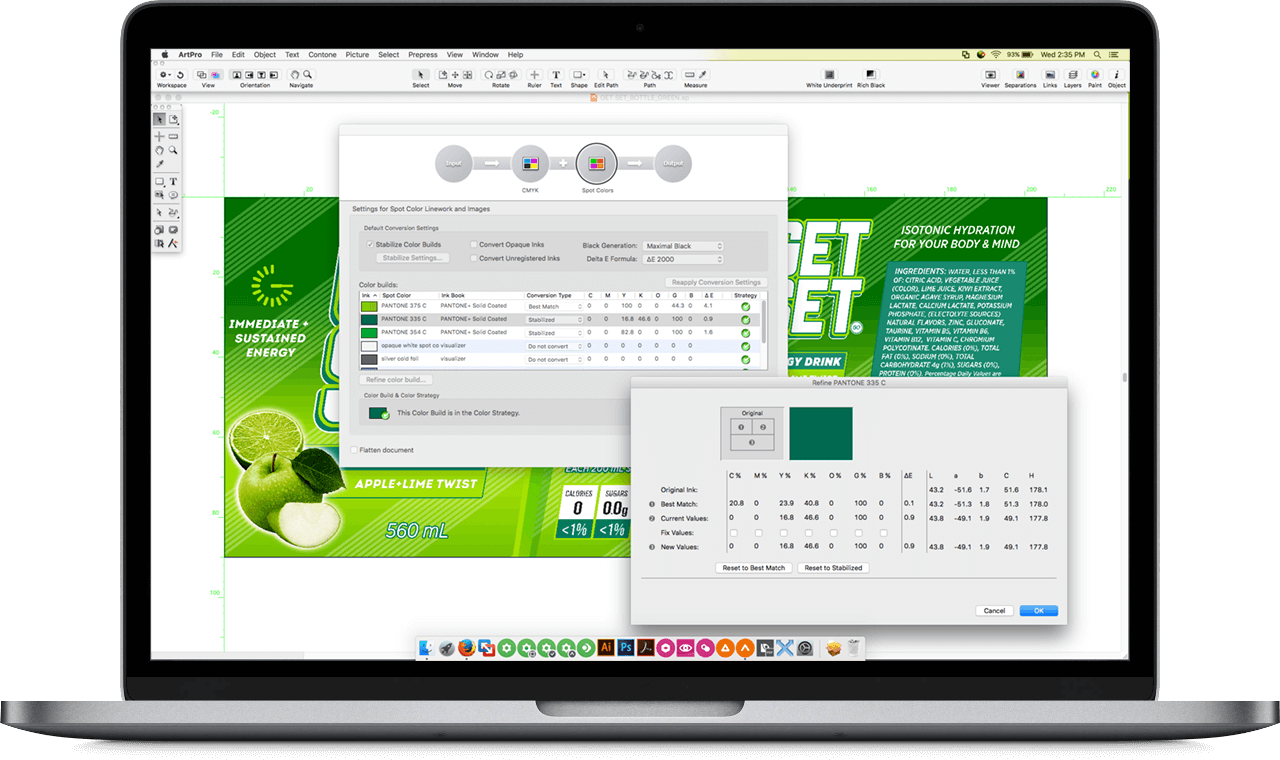

The Color Engine enables color management across the packaging and print supply chain. At the heart of the Color Engine is a central color database for all color critical data.

Color consistency is critical in brand recognition. Defining accurate brand and spot color standards is the first step in maintaining consistency. The next step is using these color standards in all packaging design and production applications.

Testimonial

If you do not have a measurable color management process to help converters stay on track, you are not going to reproduce print on a consistent basis.

Jeff Hall, Quality and Color Process Manager, Schawk!, USA

Download this free guide now.

Color Engine allows you to successfully manage brand color expectations.

It has two components:

Pack Proof provides color-accurate contract proofing to a selection of inkjet printers.

Brand packaging makes extensive use of designer (spot) colors and is produced using a wide range of print processes including digital print, offset, gravure and flexography with multi-color process printing.

Having an accurate proof early in the life cycle sets the correct expectations and optimizes print production, avoiding costly errors and waste.

Demand for shorter packaging production runs for targeted campaigns and product variations are increasing. The packaging printer needs to meet these challenges in a time and cost effective way. Extended gamut printing is one of the ways to do this.

Extended gamut printing allows you to print faster with superb quality while lowering you printing costs.

Equinox is Esko's solution for the implementation of extended gamut printing.

Equinox standardizes your printing presses on any set of 5, 6 or 7 inks of your choice. With this color management tool you save on inks (and plates) for your packaging work and you save time as the press change-over workload between jobs is reduced to merely changing printing plates.

With PantoneLIVE, the digital brand color lives in a secure, centralized cloud ecosystem where it’s accessible to brand owners, designers, production people, anyone and everyone in the supply chain, anywhere around the globe.