When leading labels business Skanem was looking to ensure its prepress department was running as efficiently as possible, it knew Esko solutions such as ArtPro+ and Automation Engine would deliver.

Skanem is a leading producer of self-adhesive labels, with 11 production sites employing more than 1,000 people across eight countries in Europe, Asia and Africa. Headquartered in Stavanger, Norway, Skanem offers innovative labelling solutions to the Personal Care, Food, Home Care, Pharmaceutical, Automotive, Beverage and Industrial market sectors. Working closely with customers, Skanem delivers a smarter, customized solution which is best suited and most cost-efficient for its customers.

With over a century of experience in the packaging industry, Skanem has achieved continuous growth and strong customer relations through understanding its customers’ needs, addressing the latest market trends and underwriting its work with a service guarantee to customers; a reassurance that they will deliver on time, no matter what.

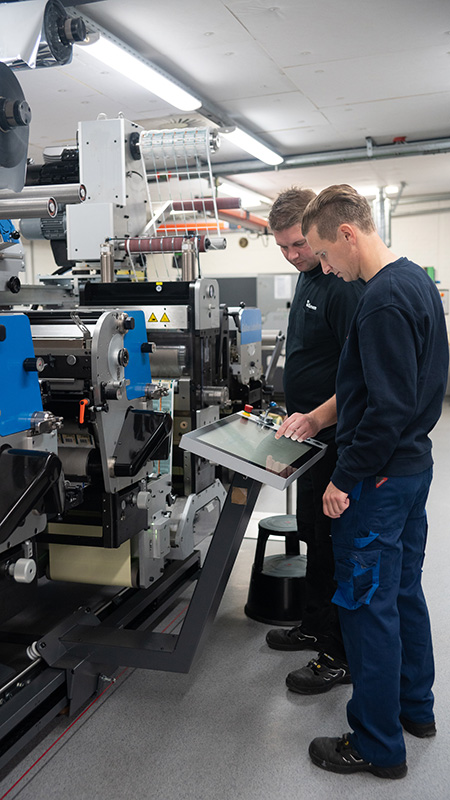

Its facility in Hobro, Denmark, offers something truly unique to customers by mixing and matching technologies in-line, with offset, screen, flexo (adhesive, liner or front), hot foil and die-cutting processes all on the same run. With the latest addition to this setup being a hybrid press with 8-color inkjet and flexo in-line, it clearly illustrates the need for software that helps maintain structure in the files.

Testimonial

As we knew we wanted to establish a PDF-focused workflow, it was the perfect time for us to build the whole workflow around ArtPro+ and Automation Engine.

Alex M. Balling, responsible for digital workflows, Skanem, Denmark

Since its beginning in 1905, Skanem has developed strong customer relations and delivered products and services of high quality. Skanem has also continuously invested in equipment, technology and digitalization in order to stay ahead of the market trends and to be leading in the markets where it chooses to operate.

“As a huge global business, Skanem uses a whole range of Esko products at its various facilities,” said Alex M. Balling, responsible for digital workflows at the Skanem facility in Hobro. “When I joined in January of 2019, one of my first responsibilities was to implement a move to the newest and most efficient software. Just as we were migrating everything across to Automation Engine to manage our workflow, Esko was launching version 18 of ArtPro+. As a long-term user of Esko solutions from previous roles, I was aware that this version took some big steps forward, especially in terms of its relationship with Automation Engine."

"As we knew we wanted to establish a PDF-focused workflow, it was the perfect time for us to build the whole workflow around ArtPro+ and Automation Engine. That’s why the entire process has been built from the ground up to ensure we use Automation Engine and ArtPro+ to more effectively and efficiently handle the prepress workflow of all our customer files.”

Testimonial

With ArtPro+, while the file is in a PDF format which can be read by anyone – and this is obviously ideal for customers – it also allows us to store all the technical information in the file.

Alex M. Balling, responsible for digital workflows, Skanem, Denmark

ArtPro+ is the latest generation native PDF editor for packaging prepress from Esko. Not only does ArtPro+ reduce unintentional errors when editing, but it also enables users to automate repeating tasks without the need for any special programming skills. Working with native PDF files, ArtPro+ is compliant with latest PDF for packaging standards such as ISO 19593 and imports normalized PDF and ArtPro files, saving metadata such as barcode information or screening information. PDF files edited with ArtPro+ are also self-contained, holding all image, font and profile information for trouble-free output and file sharing.

“Our operators had been using the previous ArtPro tool, so this was obviously a big change for them,” explained Alex. “But the learning curve is impressively flat for someone coming from classic ArtPro. The strong focus on print production over graphical design really sets ArtPro+ apart as a PDF editor, so while the team had to get used to the new tools and shortcuts, within a very short period they found that it was making things much, much quicker for them.”

“The synergies between ArtPro+ and our workflow in Automation Engine are terrific, specifically relating to the Action Lists in ArtPro+,” he added. “We use these a lot, building bespoke customer-centric lists, and it is significantly quicker with ArtPro+ than with any other tool.”

Testimonial

Not only does ArtPro+ reduce the time needed for operator input, but also significantly reduces errors and reworking, therefore increasing productivity and efficiency.

Alex M. Balling, responsible for digital workflows, Skanem, Denmark

Alex said that the team at Skanem had immediately recognized how easy ArtPro+ had made managing all the aspects of a production file. “Our production is not limited to just one production technique,” he said. “We have many jobs that require a combination of processes in the same file, for example offset and flexo, so our files can be very complex. Yet with ArtPro+, while the file is in a PDF format, which can be read by anyone – and this is obviously ideal for customers – it also allows us to store all the technical information in the file.

“Whether offset or inkjet, when trapping data for multiple processes or rules to ensure correct overprint, all the technical information is contained within the same file,” said Alex. “The time between the customer sending a file from Adobe® Illustrator®, or whichever software they have used for the design, and delivering a print-ready PDF is now much shorter. There’s no longer a need to convert incoming or outgoing files for approvals and there are no conversions required, or multiple versions of the same information.”

Alex said the Skanem prepress team strives to have a single file workflow, something that ArtPro+ makes not just possible, but simple. “We have cleaned up our folders and files immensely,” he said. “We typically now only have a one-up file and a proof sheet in the folder, whereas previously there would be a whole raft of different versions!”

Singling out the moiré detection tool in ArtPro+ for praise, Alex added: “We have very complex files , possibly containing a mix of offset, inkjet, screen and flexo information - not to mention spot and varnish, foil and other effects – and within that we need to maintain strict rules. Previously, we’d have to check each of these elements manually, which is not only time consuming but also manual work reliant on the operator to ensure accuracy. But with ArtPro+ this is made simple, with built-in tools for moiré detection and quality control. Not only does this reduce the time needed for operator input, but also significantly reduces errors and reworking, therefore increasing our productivity and efficiency.”

Alex was also keen to highlight the usefulness of the tools in recognizing text and barcodes in ArtPro+. “This is something that we’ve gotten so used to using that I have almost completely forgotten how cumbersome and error prone it used to be in retyping blocks of text or barcode values,” he said. “With ArtPro+ it’s just a literal keyboard shortcut away!”