Digital printing

Successfully integrate a digital press with conventional printing technologies.

Investing in a

digital press!

To make your digital press as profitable as possible, you will need to process, prepare and print a lot of short run jobs. Your prepress team will spend a lot of time manipulating, cleaning, and making files consistent before they are ready to be printed. Your operators may have to re-enter data multiple times.

- Free up valuable resources by automatically optimizing complex press layouts.

- Build a smarter, faster, safer, stronger workflow.

- Leverage predictive intelligence to push your digital press to the max.

5 ways to prepare your business for digital printing

Download your free e-book today.

Quote

Handling of short run orders requires a very high degree of automation in order to meet shorter lead times, while sustaining profitability.

Peter Overbeek, Managing Director, Eshuis BV, the Netherlands

Prepress

Jobs are getting shorter and customers are demanding faster turnarounds. A volatile combination but dedicated prepress carries the load. Free up valuable resources by automatically optimizing complex press layouts with a completely automated workflow solution.

Read more about Automation Engine

The Esko DFE

The Esko Digital Front end (DFE) is a turnkey software solution that enhances the performance and usability of a digital printing press. It creates workflows that help packaging and label printers in their transition to digital production. It is sold by press manufacturers who are OEM partners of Esko.

Color Preflight

Color Preflight for Automation Engine increases the efficiency of the press. It allows operators to use the most efficient ink set and reduce unnecessary print time. Color Preflight for Automation Engine also allows you to make use of EPM (Enhanced Productivity Mode) with confidence.

HP Indigo customers report improved color consistency and 17 hours extra press capacity per month.

Variable data printing

Looking for an easy way to create and work with Variable Data Printing (VDP) jobs on a digital printing press? Dynamic VDP for Adobe® Illustrator® is variable data printing software designed specifically for packaging applications such as labels and folding cartons.

Support for mixed printing processes

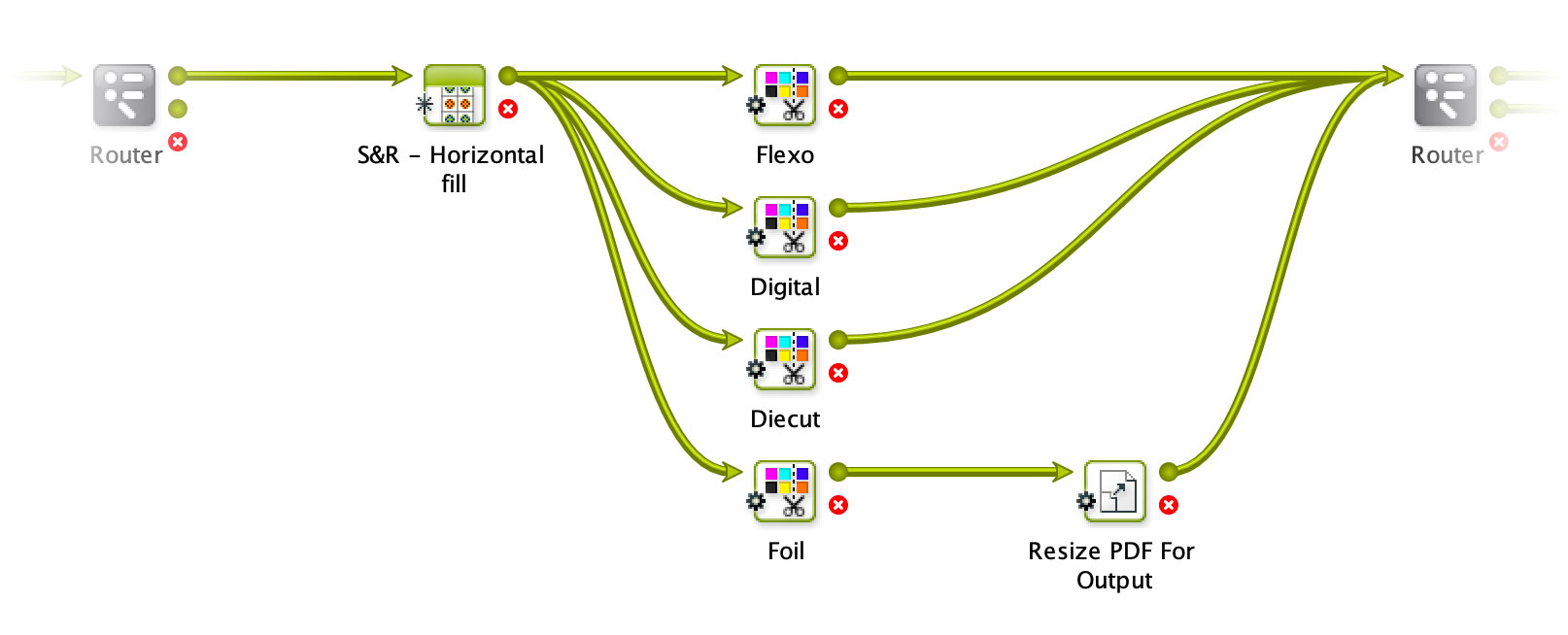

With Support for Mixed Printing Processes, Esko Automation Engine sets up an automated prepress workflow with an intelligent router that checks the printing process metadata, routing each separation through a dedicated path of an automated workflow.

The result: faster throughput, greater flexibility, more uptime, improved quality of output without duplicate efforts.