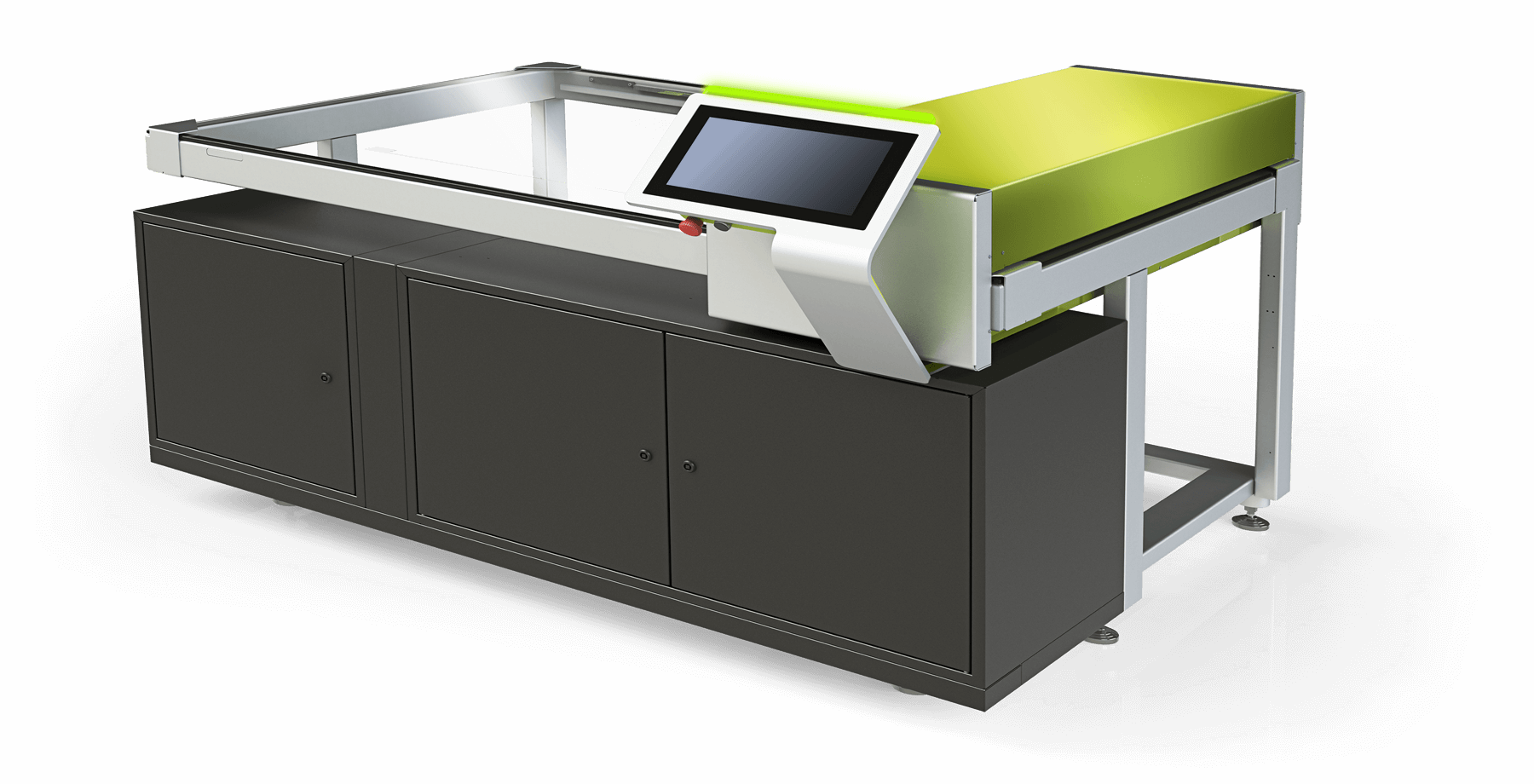

CDI Crystal 4835

Your best match, based on your answers, is the CDI Crystal 4835 flexo imager.

Together, we believe you can do great things!

The CDI Crystal 4835 has a maximum plate size of 25” x 30” (635 x 762 mm) and it comes with different optics depending on your needs. Want to do more in less time? Optics 80v2 give the fastest throughput for this model, while Optics 100v2 bring even more productivity for corrugated plate imaging.

15 1.5 m²/h - 43 min.

25 2.5 m²/h - 26 min.

40 4.0 m²/h - 16 min.

80 8.0 m²/h - 8min. i

See what Esko flexo imagers can do for your business – download our free guide now.