If your norm is rushed, last-minute jobs with inconsistent quality, you aren’t alone. Traditional multi-step flexo platemaking processes are likely causing errors and reworks, reducing your press uptime and, ultimately, harming the productivity and profitability of your operation. The good news? Creating up to date, streamlined, next generation flexo platemaking processes is easy!

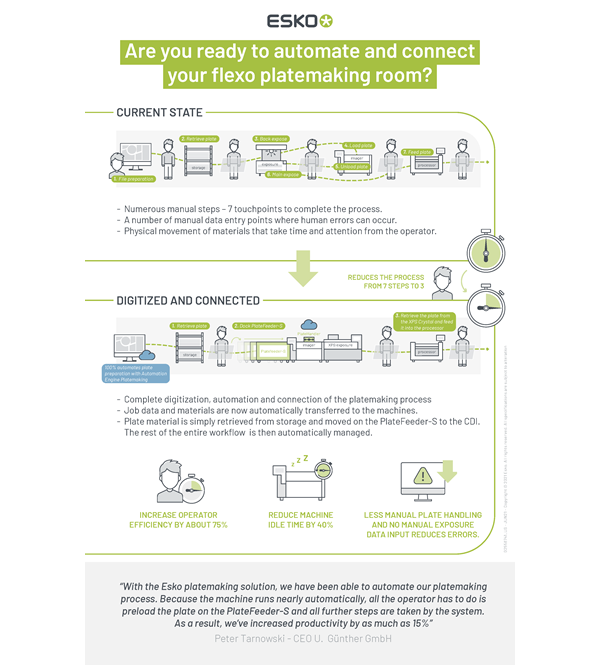

The flexo platemaking process can include multiple complex and manual steps, which not only take time, but create ample opportunity for human error, too. So, let’s redefine flexo platemaking from scratch. Instead of sending a flexo plate through up to seven manual steps, the CDI Crystal XPS from Esko offers a coordinated, linear, automated process. The integration and automation of digital imaging and LED UV exposure improves consistency and overall ease of use. This solution not only frees up your operators’ valuable time but also reduces maintenance and the footprint of your flexo equipment.

Ready to see how a CDI Crystal XPS from Esko can help your business?

We’d like to invite you to have a one-on-one demo, to see platemaking in

action, all from the comfort of your desk. Watch live as the system is

remotely controlled by one of our flexo experts to show how it could

benefit your company.

Contact one of our specialists to get a demo.

Want to know more? Want to know more? Visit these pages.

Find out the best size of plate imager for your business needs.

Standardize the generation of plates and remove all non-value-added tasks from the process.