L’Etiquette Adhésive, Lons, France, Based in Lons, Pyrénées-Atlantiques, France, and founded in 1979, L’Etiquette Adhésive designs and manufactures labels for the food, pharmaceutical, cosmetics, chemical and wine industries in the South West of France and across the country. The company handles the entire production process internally – from research, studio design and prepress through to printing and manufacturing - to guarantee the best level of service and quality to customers. The setup has helped the company respond to customers' demands year-round and to achieve a delivery performance rating of more than 98% and an annual turnover of €5.5M.

Expertise in flexo and digital printing techniques and different finishing methods such as gilding, screen printing, embossing and booklets, enables L’Étiquette Adhésive to meet customers’ expectations in terms of quality, cost and service. This technical know-how is one of the factors that helps them stay ahead of the competition.

Company director Stéphane Clavier took over L’Etiquette Adhésive at the beginning of 2019, and the business currently employs 30 people - including three people in the prepress department who have been using Esko and CERM tools and solutions for a long time.

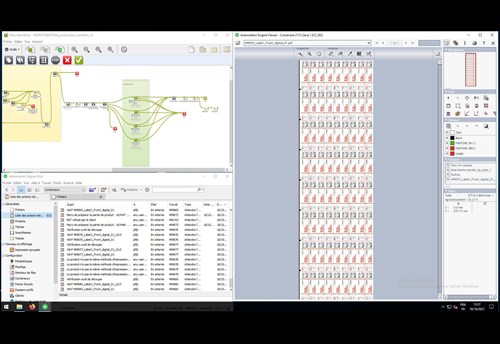

L’Étiquette Adhésive moved offices early 2020, doubling the size of its production site. As a result, the business needed to integrate new equipment to handle both the increased volume of work and to streamline processes to ensure productivity rates could at least be maintained. The company had previously adopted the CERM Management Information System (MIS) in 2006 and begun integrating Esko solutions in 2008, including Automation Engine, PackEdge, Imaging Engine, PackProof, BitMap Viewer and Color Pilot.

Testimonial

After 15 years of using Esko Automation Engine, and following the move, we needed to handle more challenging automatic step and repeat processes, for more complex jobs

Stéphane Clavier, CEO, L’Étiquette Adhésive

We decided to upgrade to the latest version in 2020, in order to fully benefit from the new tools and functionalities offered by the combination of CERM MIS and Automation Engine, and to further improve data exchange between the two systems,” said Stéphane.

This project is part of an overall digital transformation project of the company, financed by the Nouvelle-Aquitaine Region. Stéphane said that using the latest technologies available on the market enabled L’Étiquette Adhésive to preflight incoming files according to a customer profile, reassembling the files/product color codes in CERM and automatically link a color strategy to a file. This in turn automatically triggers the production order according to a work status, synchronizes job statuses, reports the release information in CERM, triggers workflow tickets automatically and automates layouts for their booklet labels and multi-page labels.

Esko Automation Engine sets the standard for optimized prepress workflow automation. The workflow software not only automates print production tasks but also integrates business systems, which speeds up the process, and more importantly reduces the error rate and need for operator intervention. Esko collaborated with CERM to ensure that L’Étiquette Adhésive benefited from Automation Engine integrated with a CERM Management Information System across the entire business.

By standardizing processes and migrating tasks to the automated workflow software, businesses using Automation Engine can reduce errors by up to 80% and process 40% more jobs without the need to increase their headcount - particularly beneficial for small and medium-sized businesses like L’Étiquette Adhésive.

Testimonial

We have actually reduced the number of operators in our team, from four to three, and we have completely eliminated bottlenecks and errors, even for orders containing 300 references and 300 product designs

Stéphane Clavier, CEO, L’Étiquette Adhésive

Stéphane said that since the company integrated Esko solutions and the CERM MIS into its prepress setup, there has been a reduction in processing times and the business has benefited from synchronized progress job statuses and automatic workflow launches.

“The new version of Automation Engine, integrated with our CERM system, allows us to achieve a large number of files printed in several stages and with different printing technologies. It saves time and improves reactivity and productivity, significantly reducing the risk of errors and omissions,” said Stéphane.

Testimonial

Thanks to Automation Engine, we are able to initiate workflows and perform a simple visual check online before files are loaded automatically onto the presses

Stéphane Clavier, CEO, L’Étiquette Adhésive

This level of automation has meant that validation and transfer of files, lead times and time spent in the prepress department have all been reduced. Stéphane said that although L’Étiquette Adhésive is already ISO9001 certified, the automated process has actually improved the company’s compliance, while downtime related to the assembly process has also been drastically reduced.

“We now receive files containing hundreds of references, which would normally create a range of bottlenecks that would need to be addressed,” said Stéphane. “The new version further improves data transfer between the two systems as they communicate even more efficiently. We also benefit from more reliable and better automated layouts for complex jobs and the fact that everything is connected to the HP presses is very convenient.

“Esko and CERM provided us with valuable support throughout the installation process,” said Stéphane. “We benefited from helpful advice and great communication from both sides. We had a pretty specific idea of what we wanted and we discussed all possibilities, the pros and cons, what the best configuration would be and how we could customize the integration. In the end we could not do everything that we wanted, but Esko and CERM offered even better alternatives that ended up being the right choice. The benefits rendered by the integrated tools are very impressive.”

L’Étiquette Adhésive is now looking towards the future and working with Esko and CERM to automate production processes even further. “We need to handle even more complex jobs,” said Stéphane. “For example, we want to automate the production of five to seven-page booklet labels or even more options, no matter the environment. Whether it is multi-passing, multi-technology, in cross-over and/or even laminated, we are driving the process forward. We are looking forward to the next updates in the summer,” he said.

Testimonial

Our current prepress editing software is also reaching end-of-life, and we will be looking at replacing it with Esko ArtPro+ to automate our process even further

Stéphane Clavier, CEO, L’Étiquette Adhésive